Lens Technology

INFOR MONO

Lenses for distance vision

For correction of a far or short-sightedness, as long as no additional eyewear is required for near sight.

INFOR MONO

Lenses for close vision

Also suitable as safety glasses for wearers of reading glasses.

The vision for distances of above approx. 40 cm is blurred.

INFOR DUO

Bifocal lenses

For the simultaneous correction of difficulties in distance vision and the age related difficultie with near vision that occurs around the age of 40 onwards.

Visible transition between close and far lens sur-faces. In the case of age related vision difficulties there are blurry areas in the intermediate distance of approx. 40 cm to 1 meter.

INFOR VARIO

Varifocal lenses

For the simultaneous correction of difficulties in distance vision and the age related difficultie with near vision.

Varifocals enable seamless vision from near to distance.

INFOR OFFICE

Office eyewear lenses

These seamless eyewear lenses can be precisely adjusted for any appropriate working distance. Such as your workplace PC screen, for example. The usable areas in the near and intermediate areas are larger than those of standard varifocal lenses.

This results in a comfortable head and body posture when performing tasks on a computer. The INFOR Officelens can be adjusted for distances of up to 4m. The lens is not approved for use when driving.

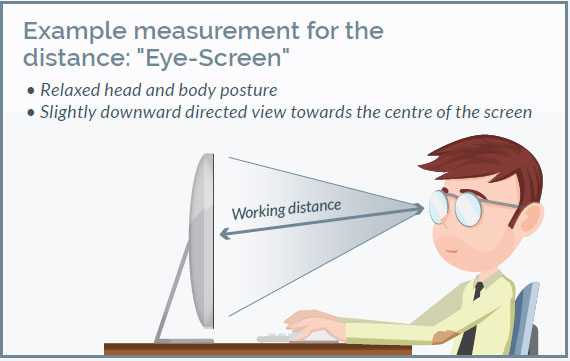

More comfort from personal computer eyeglasses with customised eyewear lenses

Eyewear with INFIELD Infor Officelenses are individually customised and adjusted to the exact centimetre for the working distance that is most often used. In addition, the desired distance should be measured in such a manner that the spectacle wearer is able to have a relaxed head and body posture at their workplace. The desired working distance should be between 40 cm and 1.5 m.

The INFOR Freeform Technology

We have incorporated the latest lens production tech-nology – ‘Freeform’ – as standard in our INFOR multifocal lenses.

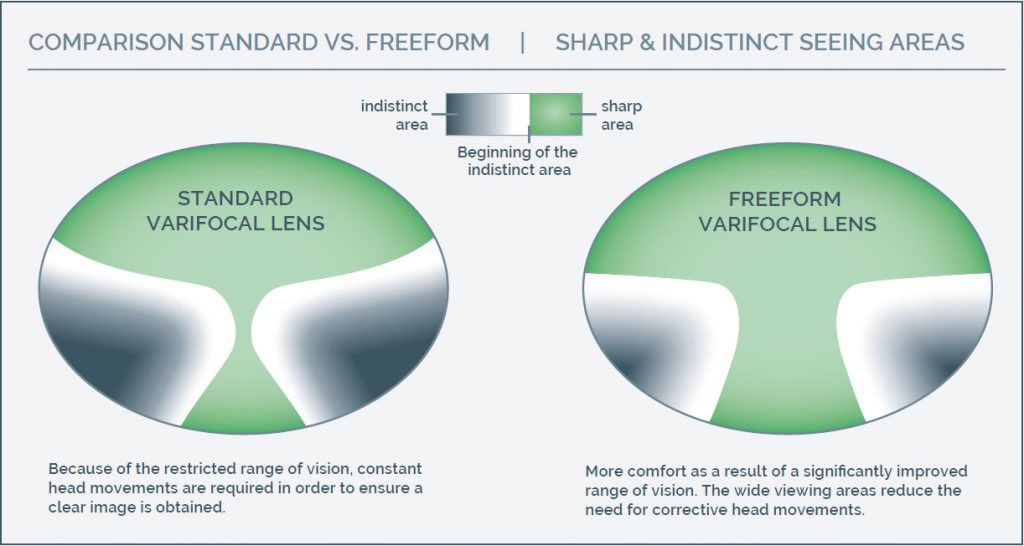

Conventional eyewear lens manufacturing is based on the processing of semi-finished basic lenses with tools in the form of segmented balls. This production method results in a relatively large area of the lens with blurry vision from the user’s perspective.

Only by utilising latest computerised manufacturing processes and high-end calculation programmes is it possible make the digital manufacturing of the freeform lenses possible. With this process, each point on the rear lens surface is individually calculated and formed, result-ing in a substantially improved image, compared to con-ventional varifocals.

Even in the case of freeform lenses, there are qualitative differences. Whereas some lens manufacturers only use standard programming for the calculation of the lens surface, INFIELD INFOR lenses are produced using a combination of multiple calculation programmes. Among them, our group’s very own Eyepoint Raytracing Programme. By means of the Eyepoint Raytracing Programme, we compute optical properties and simulate human vision from the perspective of the eye at almost 3000 points across the lens surface.

Varifocal lenses – More and more customised

Optimised production processes for varifocal lenses however also have the consequence that it becomes increasingly difficult to switch between the lenses of various manufacturers. This is due to a certain “habituation effect” from the respective lens.

When it comes to safety eyewear for spectacle wearers, because of the nu-merous lenses offered on the market, it is not possible to take all these various lens designs into account. In ad-dition, it is not feasible to customise a lens 100 percent for a safety eyewear client. This is something which is more compatible for personal eyewear. For safety eyewear, the additional cost and time factor is not commensurate with the improved results.

INFIELD Safety has therefore developed a varifocal lens, in which the range of vision is created in a very special manner. Even more important, however, is the fact that the daily switching between personal and safety eyewear, is as comfortable and easy as possible for the wearer.

The right material for every requirement

When using safety glasses for spectacle wearers, the selection of the right lens material depends on usage requirements, work environments and fields of activity. INFIELD lenses are made from both plastic and mineral glass.

Plastic lenses provide particularly good protection against mechanical hazards and are refined with special coatings to meet the individual work requirements of the spectacle wearer. In addition, plastic lenses are very light and can be adapted very precisely to the specific visual impairments.

Plastic material CR 39 – Index 1.5

lens labelling: GA1SCE

Characteristics

- Low weight

- Chemical resistant

- Hardly any spark penetration during grinding and welding work

- Recommended for lens values up to +/- 3 dp

Plastic material – High index 1.6

lens labelling: GA1SCE

Characteristics

- Very light weight

- Chemical resistant

- HC* provides very good scratch resistance

- 100% UV protection

- Largest delivery range

- Thinner than the lens material with high index 1.6

- Hardly any spark penetration during grinding and welding work

Plastic material – High index 1.67

lens labelling: GA1SCE

Characteristics

- Very light weight

- Chemical resistant

- HC* provides very good scratch resistance

- 100% UV protection

- Largest delivery range

- Thinner than the lens material with high index 1.6

- Hardly any spark penetration during grinding and welding work

Polycarbonate Index 1,59

lens labelling: GA1FCE

Characteristics

- Very low weight

- Extremely high mechanical impact resistance (BT)

- 100% UV protection

- Tinting levels from 10% to 85% possible

- Maximum lens values -8/+4 dpt

- Maintains very good scratch resistance thanks to HC*

- Hardly any spark penetration during grinding and welding work

- Suitable for full-vision safety glasses BT (Defendor RX)

Polycarbonate BT Index 1,59

lens labelling: GA1BTCE

Characteristics

- Very low weight

- Extremely high mechanical impact resistance (BT)

- 100% UV protection

- Tinting levels from 10% to 85% possible

- Maximum lens values -8/+4 dpt

- Maintains very good scratch resistance thanks to HC*

- Hardly any spark penetration during grinding and welding work

- Suitable for full-vision safety glasses BT (Defendor RX)

Trivex Index 1,53

lens labelling: GA1FCE

Characteristics

- Lightweight

- Good chemical resistance

- 100% UV protection

- Ideal optical characteristics

- Available for all lens values

- Tint grades of up to 15% possible

Mineral glass

For working areas containing abrasive dust, we recommended eyewear lenses made of mineral glass, because this material has the highest scratch resistant properties.

Tempered glass – High index 1.6

Lens labelling: GA1SCE

Characteristics

- Very high scratch resistant properties

- Good chemical resistance

- Less resistance to spark burns during grinding and welding work

- Available for all lens values

Choosing the right lens material

Polycarbonate – the optimal solution for the most common applications

INFIELD Safety’s non-prescription safety glasses generally meet mechanical protection class F, the lenses are made of polycarbonate. Polycarbonate is also the optimal solution for prescription safety glasses in almost all cases. The material enables the production of lenses that are as thin as possible, but still meet mechanical protection class “F”. Apart from polycarbonate, only Trivex meets this protection level, all other lens materials only reach the lower class “S”. In addition, polycarbonate offers 100% UV protection and can be combined with most of our surface coatings (ProCoat).

What requirements might require an alternative lens material?

| CR 39 | • Plastic glass without surface coating • Inexpensive solution • Welding work |

| 1.6 | • Greater resistance to solvents containing alcohol • Phototropic lenses • Office lenses |

| 1.67 | • High glass values that cannot be produced with polycarbonate and HI 1.6 • Greater resistance to solvents containing alcohol. • Office lenses • Possibly glass thickness for very high values* |

| Trivex | • Greater resistance to alcohol-based solvents in combination with "F". • Outstanding optical properties in combination with "F". |

| Hartglas | • Very good chemical resistance • Very high surface hardness |

| * the advantage in thickness is much smaller with safety goggles than with “private” goggles |

|

ProCoat – The optimal protection for all working conditions

Our coating technology has developed from many years of experience in the development of products for occupational safety / personal protection equipment. Our problem-specific solutions for very hazardous situation.

***

ProCoat HC – super scratch resistant

With this thin coating on the lens surface, the lens receives especially high scratch resistance properties. It is protected against environmental influences and resistant to wear. It is also easy to clean and maintain. In addition, the hard coat-ing improves the protection against chemical influences.

| Coating(s): | Hard Coating | ||

|---|---|---|---|

| HC | Designation (abbr.): | HC |

***

ProCoat SAR – Anti reflection coating

A mirror reflects up to a 96% of light. That is why we can see ourselves in it. Eyewear lenses (even though they are transparent and clear) still reflect approx. 8% of the light that hits them. This results in unpleasant reflections on the rear surface of the lens, causing vision irritations. In addition, the light transmission is restricted due to the reflection on the front lens surface. Anti-reflective coatings on eyewear lenses increase the light transmission by up to 99%. Visual discomfort from light being reflected into the yes is almost completely eliminated.

| Coating(s): | Super Anti Reflex | Hard Coating | ||

|---|---|---|---|---|

| CLEAR SAR | Description(s) (abbr.) | SAR | HC |

***

ProCoat OSC – Multi coating (hard coat + anti reflection oat + clean efect)

In addition to anti-reflective properties, this coating also offers extraordinarily high scratch resistant properties and a cleaning effect. OSC-coated eyewear lenses are especially well protected against low and high viscosity substances, along with other particle and environmental influences. Thy are very easy to clean and care for.

| ProCoat | Coating(s): | Super Anti Reflex | Hard Coating | Clean Code | |

|---|---|---|---|---|---|

| OSC | Description (Abbr.): | SAR | HC | CC |

***

ProCoat OptiFog – Multi coating (hard coat + anti reflection oat + anti-fog)

The eyewear lens receives a highly effective anti-fog finish,in addition to an anti-reflectioncoat and hard coat. Lenses with this coating are therefore especially suitable for working environments with diffuse lighting conditions and frequent changes in temperature / humidity. When necessary, the anti-fog coat is reactivated by means of the OptiFog Activator eyewear cloth.

| ProCoat | Coating(s): | Super Anti Reflex | Hard Coating | OptiFrog | |

|---|---|---|---|---|---|

| OptiFog | Description: | SAR | HC | AF |

***

ProCoat AF – Anti-fog

The big advantage of this coating is a permanent anti-fog effect. Compared to the Optifog coating, no additional cleaning cloth is necessary. This coating is also characterized by a high level of scratch resistance. A combination with a super anti-reflective coating is not possible for physical reasons.

| ProCoat | Coating(s): | Hard Coating | OptiFrog | |

| AF | Description(s): | HC | AF |

***

The Blueprotect coating is particularly suitable for people who work a lot in front of a screen while wearing safety glasses. Here, the OSC coating is supplemented by a filter that protects against the unnaturally high proportion of blue light when working on a screen and supports relaxed vision.

| ProCoat | Coating(s): | Multi-coating | Blue filter | |

| BPR | Description(s): | OSC | BF |

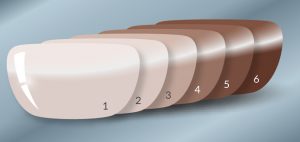

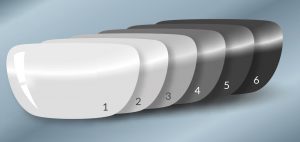

Permanent tints

Colour scheme and tint grades

If tinted eyewear lenses are required, the colours brown and grey can be selected in various tint grades. The se-lection of the tint colour is primarily a matter of individual taste and also dependent on the colour of the eyewear frame. Various tint grades enable the wearer to customise the lens to their requirements.

| Brown tints | Level | Intensity | ||

|---|---|---|---|---|

| Protection from natural glare |  | 1/2 | 10 & 15% (weak) |

|

| Various tint grades | 3/4 | 30 & 60% (middle) |

||

| Increased contrast | 5/6 | 75 & 85% (strong) |

||

| Warmer, more pleasant visual impression | ||||

| Grey tints | Level | Intensity | ||

|---|---|---|---|---|

| Protection from natural glare |  | 1/2 | 10 & 15% (weak) |

|

| Various tint grades | 3/4 | 30 & 60% (medium) |

||

| Ideal for light sensitivity, because grey is subjectively perceived as darker | 5/6 | 75 & 85% (strong) |

||

Weak tint of 10 and 15%

This tint grade can be worn throughout the entire day, as well as when driving a car at night. Because of the low level of the tint this can prevent eye fatigue and headaches. Due to the lightness of the shade, this tint only offers minimal glare protection.

Medium tint of 30 and 60%

This tint grade offers protection from more severe light sensitivity. This degree of tint should not be used when driving at night.

Strong tint of 75 and 85%

This tint grade offers perfect glare protection from the sun’s rays. Classic sun protection lenses are made with a tint of at least 75%. They are also not suitable for night driving.

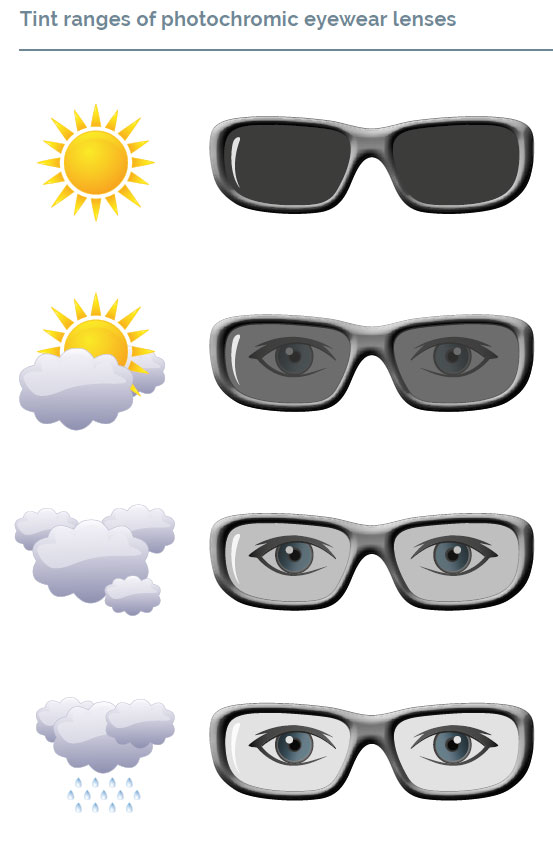

Variable tints

Photochromic eyewear lenses – self tinting from 7 to 85%

Photochromic eyewear lenses have molecules that react to UV radiation. The lenses automatically darken as the level of UV increases. This self-tinting ensures an optimal adjustment to changing light conditions. The wearer longer needs to switch between normal eyewear and sunglasses. Photochromic eyewear lenses have a base tint of 7% and available in grey or brown tint.

Tint strength approx. 75-85%

In the case of bright sunshine, UV radiation is at its highest and the eyes require intensive sun protection. The eyewear lenses darken up to the maximum tint.

Medium to strong tintapprox. 30-60%

In partly cloudy conditions with sunny intervals, there is always an increase in UV radiation. The eyewear lenses in this case darken to a medium to strong extent, depending on how the clouds and sunny periods are distributed.

Weak to medium tint approx. 10-30%

In the case of cloudy weather and diffused light, the UV exposure is minimal. The eyewear lenses darken only minimally.

Weak base tintapprox. 7%

There is no UV radiation. Perhaps in the case of very cloudy conditions, in the dark, or when performing tasks indoors.

Temple technology

Perfect fit & optimal hold

The temple is an important part of safety eyewear. It is primarily responsible for the hold and the comfort of the safety eyewear. INFIELD Safety offers numerous customised solutions.

Softflex Fit

The smooth and flexible slings of the Softflex Fit temple tips absorb the pulling force from the temple and prevents pressure behind the ear. In addition, by means of the smooth metal core, the rubberised temple can be individually adjusted to the head anatomy. This ensures a perfect, non-slip fit of the safety eyewear. Frames which feature adjustable length temples can also be adjusted to suit specific anatomical profile.

Easy Fit

These universal temples stabilise the safety eyewear by means of the anatomical shape and flexible materials. The safety eyewear therefore automatically sits in the perfect position and pressure free.

Easy Fit Soft – with additional rubber support

With an additional smooth rubber support, these optimised Easy Fit Soft temples ensure an even better hold and more comfortable fit of the eyewear, even during periods of heavy perspiration.

Basic Fit – Metal temple with non-slip rubber tip

This standard variation benefits from a pliable metal core which can be adjusted anatomically to suit the wearers profile.

Useful Information

Information about the lens values

The lens values are determined by an optician or an eye doctor. In addition, the pupillary distance of the wearer is measured. This measured parameter is documented on an eyewear prescription.

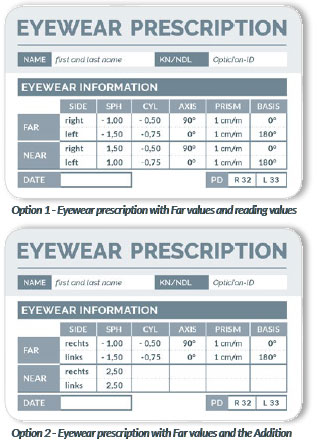

Information included in the eyewear prescription

| Term | Explanation |

|---|---|

| Sph (Sphere) | Proportions of the near-sightedness or far-sightedness in the defective vision |

| Cyl (Cylinder) | Only provided, if there is a corneal curvature |

| Axis | Location of the corneal curvature of the eye | The value of the axis determines the position of the cylinder effect in the lens |

| Prism | A prism correction corrects a heterophoria (misaligned eyes). The value is given in cm/m |

| Basis | Gives the position of the heterophoria |

| Near | Lens value, in order to see nearby objects |

| Far | Lens value, in order to see objects at distance |

| Addition (ADD) | When ordering varifocal lenses, both the ‘Far’ value and the ‘Near’ value must be provided. For purposes of simplification, the ‘Near’ value can also be indicated as Addition (ADD)". (Near value = Far value + Addition) |

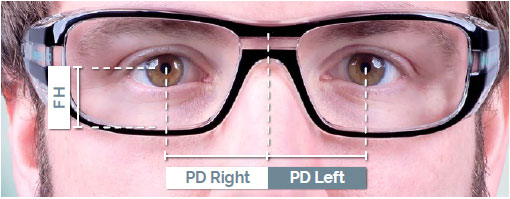

Pupil distance (PD)

The pupil distance describes the distance between the centres of the pupils. The individual pupil distance is measured from the centre of the pupils to the nasal root (PD Right + PD Left = PD). As a rule, faces are not symmetric, which can lead to different measurements for the right and left eye.

The eyewear is then manufactured in such a manner that the optical centre of the eyewear lens is directly in front of the pupils. This measurement is especially important, because a deviation from the measured PD can lead to headaches and nausea.

Fitting height (FH)

Because every face has its own unique shape, all eyewear lenses are despoke. To enable accurate manufacture, the pupil distance and the fitting height must be determined in advance. The fitting height is required for varifocal lenses, officelenses, bifocal lenses as well as single vision lenses with high lens values. The proximity height depends on the eyewear frame. It is measured from the bottom, inner frame edge to the centre of the pupil. The proximity height can be adjusted depending on whether varifocal or bifocal lenses are required.

Defective vision and its consequences

In order for a person to be able to observe an object (image) sharply, the rays of light that travel from an object must be projected onto the retina of the eye in an exact manner. Should this process be hindered as a result of the person’s specific anatomy, it is called defective vision of the eyes.

Near-sightedness (Myopia)

The eyeball is too long or the refractive power of the eye lenses is too high. The image information is not projected sharply on the retina, but in front of it (near-sighted). Objects that are further away appear unclear.

Far-sightedness (Hyperopia)

The eyeball is too short or the refractive power of the eye lenses is too low. This means that the image information is not projected sharply on the retina, but behind it (far-sighted). Objects that are close appear unclear.

Corneal curvature (Astigmatism)

Compared to the eye, the cornea is not spherical but oval in shape, like a football. This means that light is not projected onto the retina as a point, but in the form of two differently positioned lines. Objects, both near and far, are perceived as blurred.

Age related (Presbyopia

As we all grow older, the elasticity (refractive power) of the eye lens constantly decreases. The ability of the eyes to see objects that are nearby clearly always leaves much to be desired. In the same way as far-sightedness, the image information is projected sharply not on, but behind the retina. Objects that are nearby therefore appear unclear.

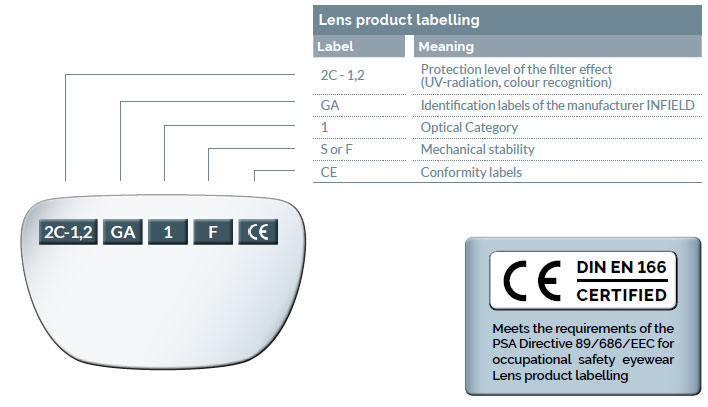

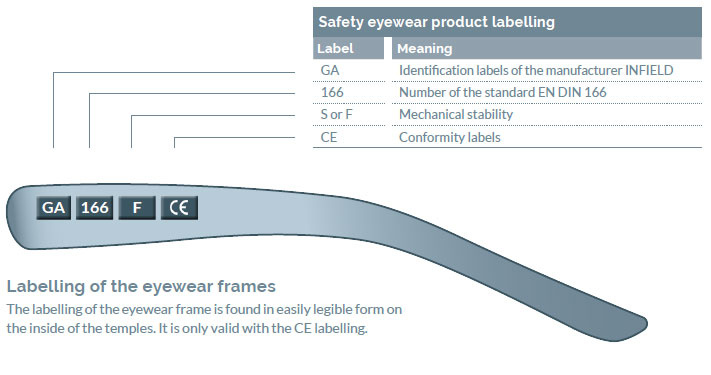

Labellings according to DIN EN 166

The labelling of the lenses as an engraving on the upper edge of the protective lens contains only the most necessary information so that the field of vision is not restricted.