- Work safely

- Communicate better

- increased productivity

In just three steps:

Noise measurement & frequency analysis

The selection of hearing protection is determined by the so-called TOP list:

- Technical,

- Organizational and

- Personal measures.

The sound level measurement is carried out by the responsible professional association or the company’s safety specialist. Based on this measurement, the employee’s personal stress is determined.

First you try to implement a noise reduction program. If this is not possible for technical reasons, organizational measures are taken to protect the employee from excessive noise exposure. If these measures do not work, the employee is provided with hearing protection.

Product selection (material & filter)

When choosing the right hearing protection, the following points should be taken into account: wearing time, noise situation, wearing glasses/beards, easy handling, compatibility with other PPE. INFIELD offers 3 different materials for hearing protection:

- COMFORT – A soft silicone material, suitable for almost any work situation.

- BASIC – A hard, silicone-free acrylic material for harsh industrial and sterile work environments.

- PREMIUM – A thermoplastic PU material that is rigid at room temperature and fits perfectly to the ear canal when worn in the ear.

Specialists working nationwide are on site at your location

To produce the otoplasty, you first need to take a mold of the external auditory canal and part of the auricle. Before the impression is taken, the ear canal and eardrum are checked first. A cotton tamponade is then inserted into the ear canal and the impression material is introduced into the ear canal without pressure using an injector gun. After a few minutes, this impression is removed and sent to our otoplastic laboratory for processing.

Our nationwide field service specialists will arrange appointments at your location. The ear impressions of each employee are taken.

A call to 0212-23234-0 or an email to info@infield-safety.de is enough and we will put you in touch with your responsible field sales representative. They will also advise you in detail about the various products and make you an appropriate offer.

The instruction and handling of hearing protection is carried out directly at our customers’ premises either by our field staff or the occupational safety specialists on site.

Useful information

NOT BEING ABLE TO SEE SEPARATES YOU FROM THINGS. NOT BEING ABLE TO HEAR SEPARATES YOU FROM PEOPLE. (Immanuel Kant)

According to DGUV, 39% of all work accidents are caused by excessive noise levels in the workplace.

The dangers of excessive noise exposure in the workplace are still not sufficiently recognized and not taken seriously.

Below you will see how easy it is to protect your hearing.

THE INDIVIDUAL HEARING PROTECTION FROM INFIELD SAFETY PROTECTS HEARING AND PROMOTES PRODUCTIVITY.

Small part – big effect

Ordinary foam earplugs simply seal the ear canal. The surroundings only sound very muffled and the user feels isolated.

The individual hearing protection from INFIELD Safety is small and unobtrusive. The hearing is protected, the noise exposure is always below the critical limits.

Speech intelligibility & audible warning signals

Due to the high-quality filter technology, the hearing protection can be adapted to the individual requirements of the wearer and his workplace. Frequencies that are disturbing or dangerous to the ear are filtered out and excessive volumes are reduced. Speech intelligibility and signal perception are retained.

Perfectly adjusted

The anatomy of the ear is as unique as a fingerprint. An earpiece (known as an “otoplasty”) is made based on an individual impression of the ear canal. This otoplasty is made from skin-friendly materials. It serves as a carrier for the hearing protection filter. The user thus receives a hearing protection system that is completely individually tailored to him, his needs and his work environment.

THE EARS NEVER SLEEP – THE HEARING IS ALWAYS AWAKE

Our ears are wide awake – always. Even in our sleep we hear sirens, crying children, our snoring partner or even the ringing of the alarm clock.

HEARING DAMAGE CAUSED BY NOISE IS IRREVERSIBLE

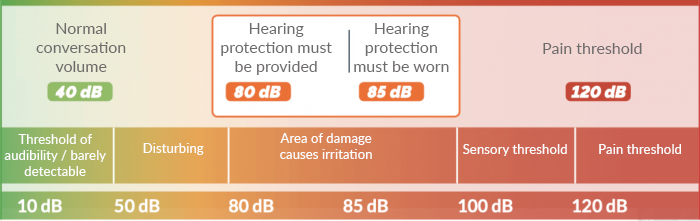

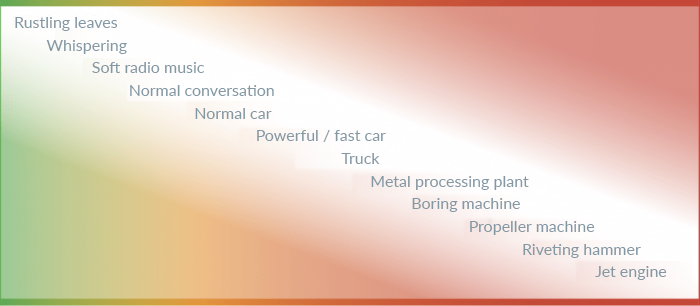

The hearing is constantly exposed to stimuli. Most people are not even aware of the health damage that noise can cause. In medicine, the threshold for possible hearing damage is a noise level of 85 decibels (dB), the pain threshold is 120 to 130 dB – this corresponds roughly to the noise of a jet taking off 100 meters away. In apartments it is typically 40 to 50 dB, in offices up to 65 dB. In road traffic, 85 dB can quickly be reached, discos and rock concerts are often significantly louder at up to 110 dB than a jackhammer at 100 dB – every three decibels more doubles the strain on the ear. In the workplace, legal regulations regulate the noise level above which hearing protection is mandatory must become. However, the hearing protection provided is often not worn at all. The wrong insulation makes the user feel isolated. It is hardly possible to communicate with colleagues and warning signals are not noticed. Some hearing protection is also perceived as uncomfortable. Wearers often complain about headaches, others about material allergies or unpleasant sweating under the hearing protection.

Symptoms of illness caused by noise:

- Tinnitus

- Stress symptoms

- Increased blood pressure

- Headache

- Exhaustion

- Difficulty concentrating

- Stomach problems

- Circulation problems

- Sleep problems

WHAT DOES NOISE MEAN:

Noise refers to sounds that, due to their structure, usually volume, have a disruptive, stressful or health-damaging effect on the environment (especially people).

Whether noises are consciously perceived as noise depends particularly on the listener’s assessment of the sound source. Despite becoming accustomed to acoustic noise, noise can continue to have an unconscious effect on the body and psyche. Noise can disrupt biological rhythms in a variety of ways. (Source: Wikipedia).

OTOPLASTICS – INDIVIDUAL EAR MOLD

The earmold is the earpiece of the hearing protection system. Comfort, function and aesthetics are largely determined by the individual earpiece. For this reason, we always place the highest value on quality and precision. For 30 years we have been producing a wide variety of earmolds in our laboratory from high-quality materials that are certified and tested according to international standards. Modern manufacturing technology combined with experienced craftsmanship enables a diverse range of products in terms of shape, material and design.

COMFORT SILICONE

Silicone is a high-quality material that impresses with its elasticity and durability. Due to its elasticity, the earmold can adapt to head movements and the associated movements of the ear canal.

BASIC ACRYLIC

Acrylate is a particularly resistant and rigid plastic. The earmold therefore cannot deform and is easy to clean. The service life is almost unlimited, but due to anatomical changes in the ear, the hearing protection should be replaced approximately every 5 years.

PREMIUM THERMOPLASTIC

This premium material is rigid at room temperature and becomes flexible when worn in the ear. Since the material can fit perfectly into the ear canal in this way, a natural wearing experience is guaranteed.

Even if it is severely deformed, the earmold always returns to its original shape thanks to the memory effect.

DIFFERENT FILTER TECHNOLOGIES

Basically, two different filter technologies are used in the customized hearing protection from INFIELD Safety.

“LINEAR” FILTER TECHNOLOGY

Perfect for loud and dirty industrial environments

The robust channel filters with 4 different insulation values are ideally tailored to all applications in industry and trade.

Areas of application:

Workplaces with high and very annoying noise levels, such as steel construction, the beverage industry, the wood industry, road construction, printing works, agriculture, etc.

Figure: Example of a select filter

FILTER-TECHNOLOGIE „LINEAR“

Perfectly tuned for a linear/natural sound

The chamber system filters in 3 different attenuation values are ideally tailored to applications where a natural sound is important.

Areas of application:

Jobs with a high level of communication, such as in the chemical industry, aviation, road construction, music, logistics, machine testing, forklift drivers, etc.

Figure: Example of a linear filter

HEARING PROTECTION IN DAILY USE

Foam ear plugs

UNECONOMICAL! – ENVIRONMENTALLY HARMFUL! – INSULATION!

Many companies still use foam earplugs. However, in the long run these are uneconomical, environmentally harmful and isolating!

Ordinary foam earplugs simply seal the ear canal. The surroundings only sound very muffled and the user feels isolated.

The individual hearing protection from INFIELD Safety is small and unobtrusive. The hearing is protected, the noise level is always below the critical limits.

Individual hearing protection system from INFIELD Safety

SUSTAINABLE AND ECONOMICAL

The wearing acceptance of individual hearing protection is significantly higher than with standard solutions. Only hearing protection that is worn protects hearing. Exposing your hearing to noise and not protecting it can lead to long-term hearing loss. Noise pollution at work is one of the most common causes of noise-induced hearing loss. Noise-induced hearing loss has been one of the most commonly recognized occupational diseases for decades (see graphic below). An international study has even shown that one in five people aged 50-60 suffers from hearing loss. Individual hearing protection is also economically worthwhile in the long term! Standard solutions appear to be very cheap at first. However, this standard protection sometimes has to be replaced several times a day and can even be more expensive in the long run. Furthermore, the costs can be calculated more easily. Through an individual solution, the employee is shown greater appreciation. Identification with the company is improved and motivation is increased. The higher quality protective equipment also points to the importance of protective care. The sustainability of the individual solution also contributes to more environmentally friendly behavior compared to disposable foam plugs. Less waste is created.